What Is CNC Post Processing?

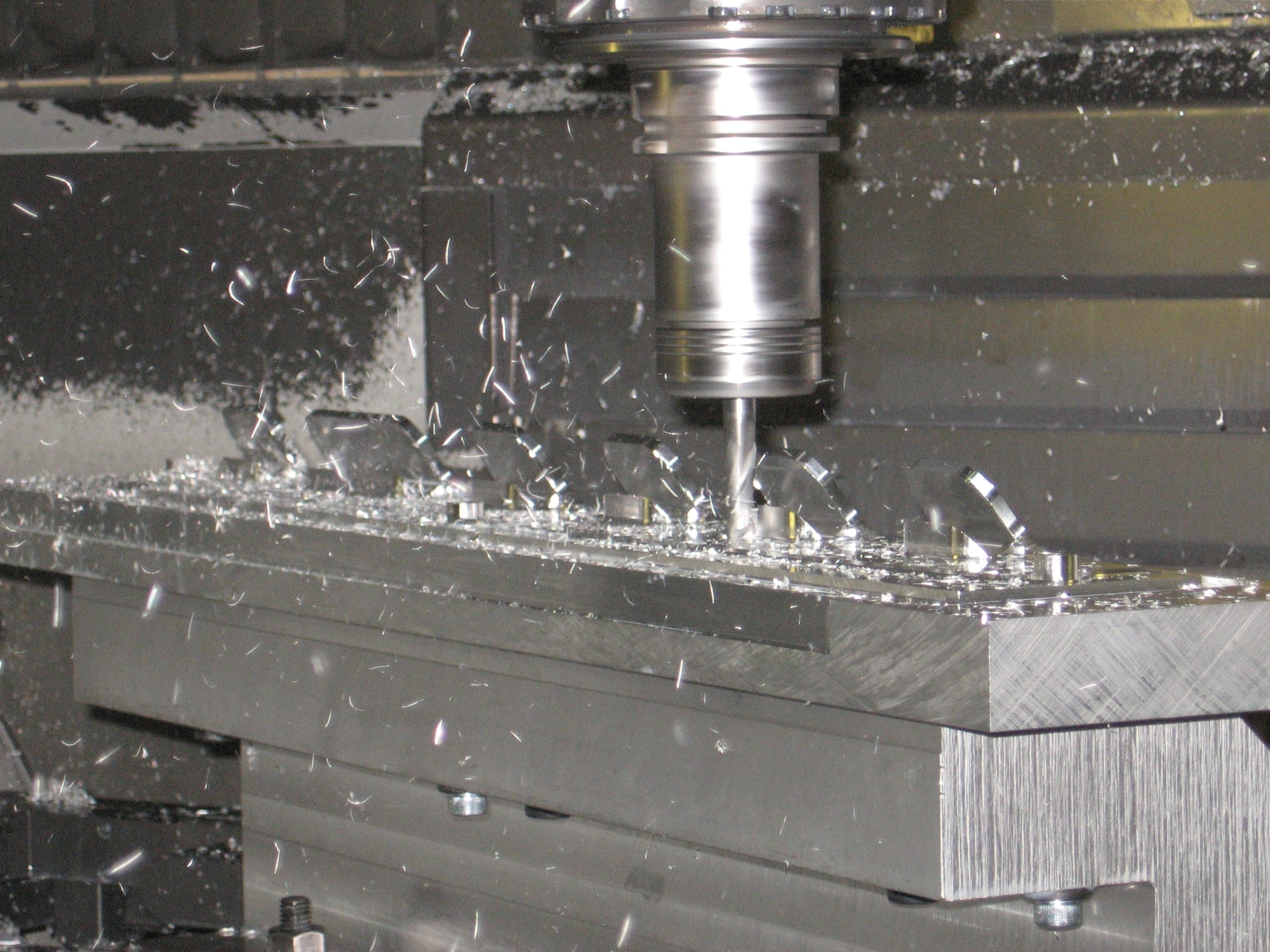

Post processing is an important step in computer aided manufacturing. Post processor software functions as an adapter between CAM software and CNC machine tool. A CAM software is used to create “tool path data” (TPD) that describes a series of milling / turning operations using various cutting tools. TPD is machine tool independent. TPD must be converted into a NC code so that it can be executed by the target CNC machine tool. This conversion is called post processing.

Post processing is important because it enables proper machining. If post processor is not configured and verified properly, it may cause loss of time and money through collisions, scraped parts, manual editing of NC code. Post processor is either an internal module of the CAM software or it is a independent software like MANUSpost. An independent post processor solution can support multiple CAM software. Features of a Proper Post Processor:

- there should be no need to manually edit the NC codes.

- should support all the functions of the CNC machine tool and the CNC cotroller.

- should provide additional functionality to cover shortcomings of CNC machine tool, CNC controller or CAM software.

- should be compatible with manufacturing culture of the company.

Feb 2015 . MANUS