The Must-Haves Of A Proper CNC Post Processor and Post Processor Editor

1. No manual editing should be required after CNC post-processing: A proper CNC post-processor should generate NC programs (G code files) that are ready to use without the need for manual editing.

2. Editing/Customization should be flexible: The post processor editor should allow for easy customization and editing. Users should have the freedom to modify the post processor according to their specific requirements, without unnecessary restrictions.

3. The editor should provide powerful functionalities: The post processor should possess robust functions to effectively address any limitations in the CNC machine tool, CNC controller, or CAM software.

4. Compatibility with the manufacturing culture of the company: A proper CNC post processor should align with the manufacturing culture of the company. This means it should be compatible with the existing workflows, practices, and preferences of the organization. A post processor that seamlessly integrates into the company's operations can significantly improve productivity.

Let’s now look at all these must have features in detail:

1. No manual editing after CNC post-processing:

While CAM companies often provide standard post-processors, they may not consider the specific parameter adjustments (PLC settings) required for different CNC machine tools or address different customer-specific requests. This often necessitates manual editing of the NC programs after post-processing to ensure compatibility.

We are aware that many companies manually modify their NC programs (G code files) after post-processing. This has almost become an industry standard for many companies. Some examples include:

-

-

Generating 3-axis tool paths for 4- or 5-axis CNC machines. Later, the rotary axes are manually rotated to the required positions, and the modified 3-axis NC program is run in these tilted/rotated rotary axis positions.

-

Manually adding/changing positioning moves at the beginning of each operation after post-processing.

-

Writing a main NC program manually and running the post processor output as a subprogram, while removing all the tool changes in the subprogram.

-

The number of examples is countless. This is all wrong. No one should alter their NC programs after post processing.

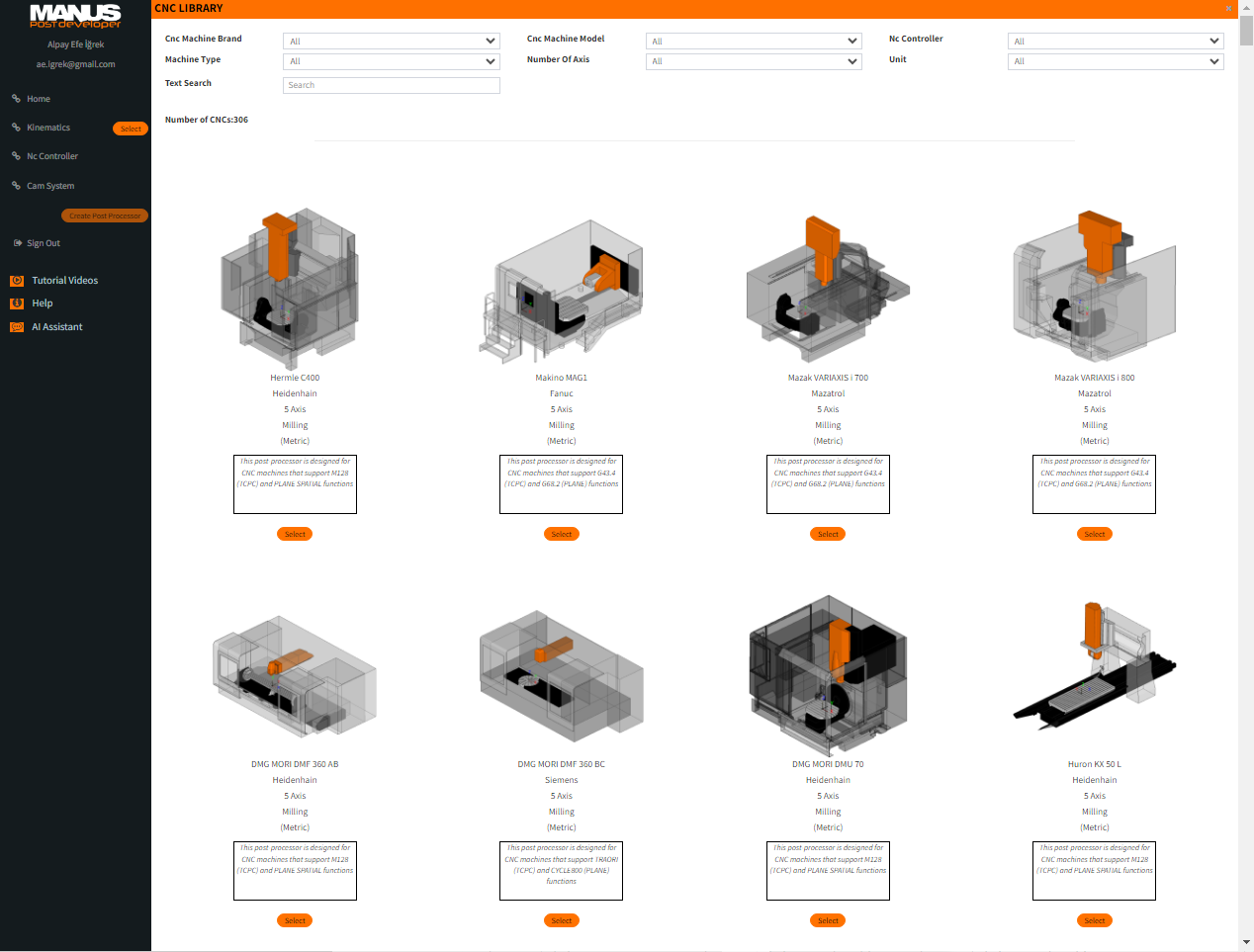

MANUSpost developeroffers a vast CNC post-processor library. You can start testing them for free. If you require any customization on these library post processors, MANUSpost developerallows you to easily make modifications according to your needs. This eliminates the need for manual editing of NC programs when using post processors within MANUSpost developer.

2. Post processor customization/editing should not be restricted and should be made easy for users:

Some CAM software, like Siemens NX, Mastercam, and Autodesk Fusion 360, allow end users to edit their own CNC post processors. However, there are some CAM software systems that do not permit customization by end users. Only resellers have access to the post editing software within these CAMs. This poses a significant problem for end users, as even for simple post processor modifications, they always have to rely on their CAM reseller for assistance. Furthermore, CAM resellers often exploit this situation to sell new versions of the CAM software.

Even for CAM companies that do allow post editing, such as Siemens NX, Mastercam, and Fusion 360, the problem still persists. This is because the post processor editing tools provided within these CAM software are outdated and difficult to use. Creating or customizing post processors using these tools requires a high level of expertise.

On the other hand, MANUSpost developer is considered to be the most user-friendly post processor design tool in the world. It features a well-designed structure, and all modifications, even complex ones, can be done in a single window with ease, unlike the outdated and inefficient post processor editors of the past. Moreover, NC program debugging is made significantly easier in MANUSpost developer. With just a few clicks, you can generate NC programs (G codes) and, by right-clicking on the NC lines, immediately see how each line is generated.

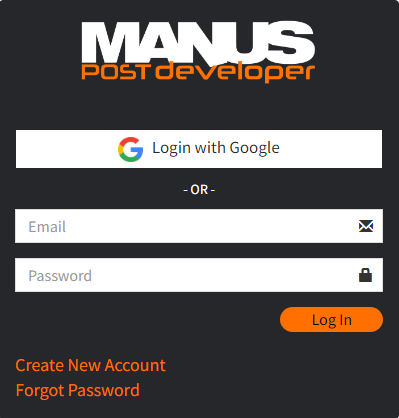

The good news is that MANUSpost developer is free to use. Simply log into the software with your existing Gmail account, as it is a cloud-based application. No credit card information is required to get started.

3. It should provide additional functionality to address the shortcomings of CNC machine tools, CNC controllers, or CAM software:

Some CAM companies prefer to provide post-processors that do not utilize the full functionality of the CNC machine tool and the CNC controller. A prime example of this is the horizontal (4-axis) milling post-processors. Almost all CAM companies require you to select the work offset center (G54, G55, etc.) as the B-axis rotation center. This poses a significant challenge for many CNC manufacturing companies since they have to generate a new NC program (G code file) each time there is a slight modification in the workpiece's location on the CNC machine table. These CAM companies compel end-users to modify the work offset center in the CAM software and subsequently regenerate a new NC program for each new part in slightly different position.

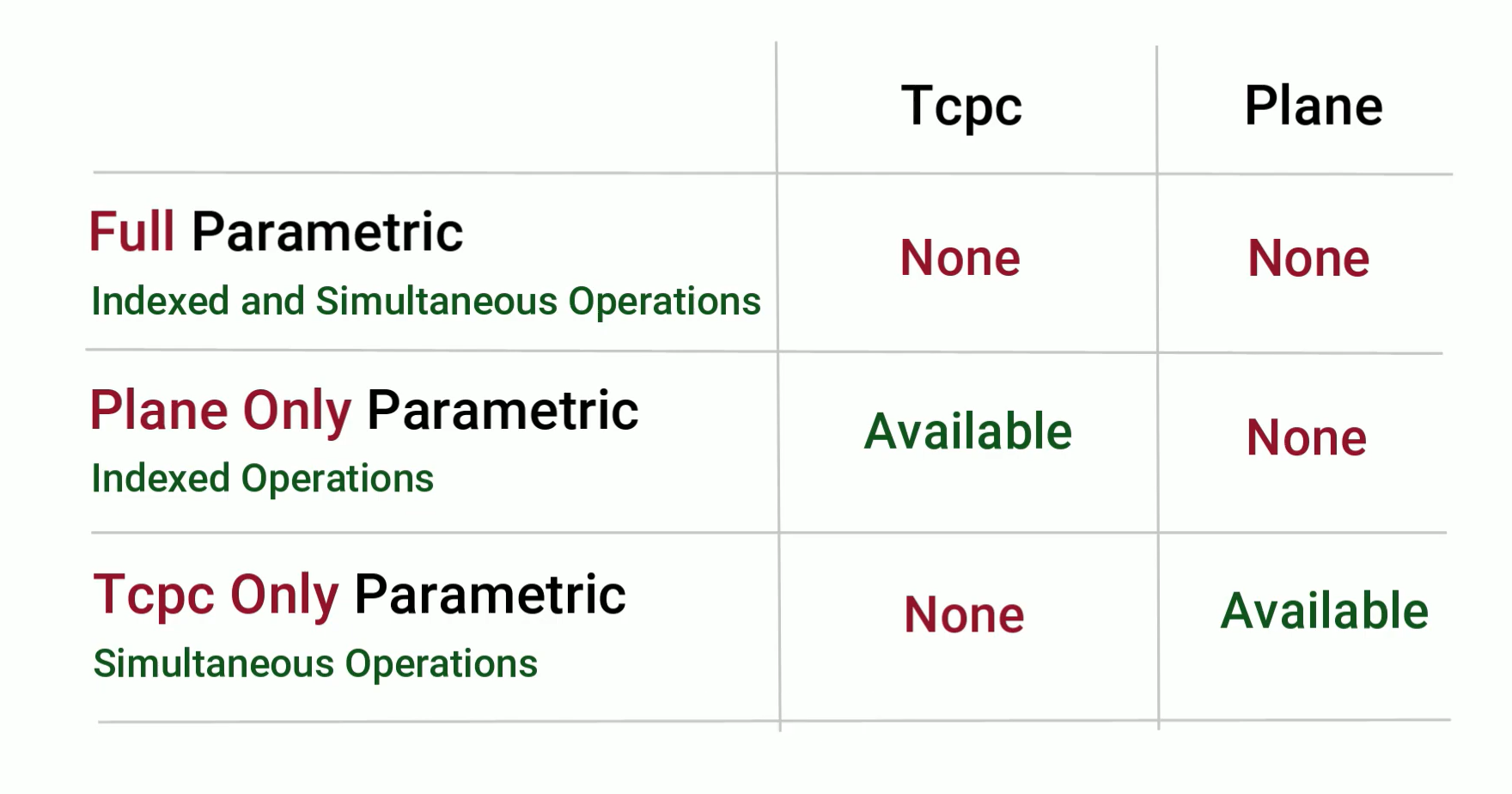

In the post processors designed in MANUSpost developer, we never enforce such limitations. We have special post processors known as "parametric post-processors" that allow you to define the work offset center anywhere you desire.

Another noteworthy example is that many CAM companies do not generate tool paths for angular heads (90-degree angular tools). Some CAM companies are completely unaware of this issue, while others require you to define the angular tool within the CAM in order to generate proper NC programs for the angular tool.

In MANUS post processors, you do not have to define the angular tool within the CAM to generate tool paths for angular heads. Simply adding a short UDE (user-defined event) will automatically activate the angular tool within the post processor, allowing you to generate the NC programs promptly.

4. It should be compatible with the manufacturing culture of the company:

As I mentioned earlier, there is a misconception among CAM companies that post processors are fixed and require no changes or edits. This notion is completely false because post processors often require significant modifications once they are delivered to customers.

Each customer has a unique culture and machining style, and they expect to see their own preferences reflected in the NC programs (G code files). For instance, some customers prefer to have the feed rates displayed at the top of the NC program, while others prefer to have information about the cutting tools used.

Some customers also require the ability to quickly modify feed rates by changing them in a single location (known as parametric feed rate tables), while others may want to create their NC programs separately as main and sub NC programs. CNC machining culture varies greatly among different companies, and all these customizations need to be accommodated. MANUSpost developer provides you with the flexibility to make any desired edits to your post processors.

To learn more about MANUSpost developer and the future of CNC post processing, you can also look at the "Future of CNC Post Processing" blog.

Future of CNC Post Processing: https://www.manusnc.com/en/blog/Future-of-CNC-Post-Processing

Jul 2023 . MANUS