What is CNC Air Cut & How to Get Rid of Them?

The unsolved problem that is always faced and causes serious time loss: Air Cuts

What are these air cuts? In fact, most of you already know, as you faced them all the time.

Air cuts basically have two types:

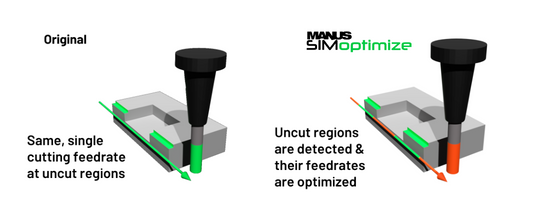

1) Even if the cutting tool is touching the surface of the cut stock, it does not constantly remove chips. You can easily notice this when you listen to your CNC: a cutting sound, then a silence, and comes another cutting sound. This happens all the time and sometimes the silences last too long. All those silences are caused by non cutting tool paths and are the signs of big machining losses.

You can also notice this problem when you examine your CAM program carefully. However, most of the time there is an urgent need for parts to be produced, you do not have much time, and it is your most important goal to create your CAM program as quickly as possible. In this situation, whether you want it or not, a lot of non-cutting tool paths are created in your NC program.

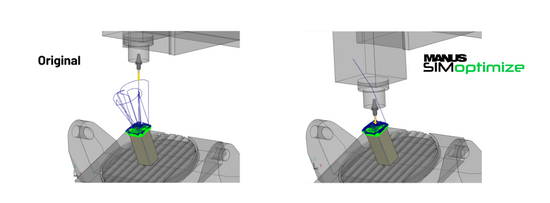

2) Now let’s examine the second kind of air cut. You can notice this type of air cut easily. While your CNC machine is running, your CNC machine unnecessarily returns to the home point. This happens a lot on multi-axis milling machines. In fact, in some parts, this happens very often and it drives people crazy. You wonder if you are cutting a part or you sent the cutting tool for a travel.

Both of these air cuts are extremely annoying, and make you lose time and money.

So, is there a solution for them?

There is now…

I would like to introduce you to the world’s first NC program based, air cut acceleration and minimization algorithms developed by Manus engineering team.

The product’s name is MANUSsi optimize…

You will hear about this product much more frequently. You can be sure of that.

MANUSsim optimize is an optimization software that uses the digital twin of your CNC. While simulating your NC program on your CNC digital twin, it optimizes the air cuts at the same time.

By doing so, MANUSsim optimize ends those two problems mentioned above.

1) It detects all the air cuts in the NC program automatically and speeds up every non cutting movement by breaking the NC lines into parts when needed. It maximizes the feed rates of every single line of non cutting move and speeds up your machining time by more than %20. Hold tight, for some companies these gains are already over 50% in our tests. I think you already understood why we keep saying you will hear about MANUSsim optimize more.

This may sound interesting to you but we liken this product to a beggar. We all saw on TV how a beggar can collect millions with the smallest amounts. This product does the exact same thing. It detects even the smallest air cuts and speeds up each and every one of them automatically without you noticing. These losses, which can seem insignificant when you look at them one by one, can provide huge gains in total when fully optimized.

The good thing is this software works with every type of CNC milling machines. It doesn't matter whether it's a 3-axis machine or a complex 6-axis simultaneous machine.

And the fact that makes us proud: This is the first and only software in the world with this capability.

2) As we have said before, the other important problem is the tool returning to the machine home point. MANUSsim optimize completely solves this problem, too. It automatically detects all unnecessarily high distance departures of the tool from the stock material and automatically positions your tool for the new operation, just above the part. In doing so, the software detects your cut stock geometry and avoids any collisions with the stock.

It completely puts an end to unnecessary home returns especially on your multi-axis CNC machines, speeds up the production and increases your profitability in every part.

We should proudly mention that, this software is also the first and only in the world.

So, is it difficult to use this software?

Absolutely not. Everything happens automatically. It automatically transfers everything (cutting tools, stock material, work piece zero coordinates etc.) from your CAM program to our software. After that all you need to do is to press the simulation start button in MANUSsim. Then, MANUSsim optimize, which is working automatically inside MANUSsim, completes all those processes without you noticing and gives you an optimized and accelerated new NC program.

Imagine having a software that speeds up your machining with just one click by 20% and more. Let’s look at what you will gain:

1. The number of parts you produce during the year will increase by 20% or more without the need for any additional CNC investment. The more parts you produce, the more you will earn.

2. Your CNC work load, electricity and labor costs per piece will decrease and your profitability will increase.

3. Your delivery time will decrease. Speeding your delivery times up will put you ahead of your competitors.

4. You will be more likely to get new business compared to your competitors, as you will offer more affordable prices without reducing your profitability. Maybe you will even start to take the jobs in their hands.

5. Finding a good CAM programmer is very difficult, it is much more difficult to machine a part in a short time if you don’t have a good CAM programmer. With this software, you will enable your inexperienced CAM programmers to machine parts quickly. You will get maximum efficiency from these programmers without decreasing your profitability.

Just be sure that using this product will enable you to acquire many other advantages and earnings.

Use MANUSsim optimize and see the other advantages for yourself. Start increasing your gain and profit today!

Jun 2022 . MANUS