6 Major Reasons Explaining Why You Need a Real CNC Simulation Now?

1) To Be Completely Sure About Your Nc Programs

Before starting real CNC machining, this is the first thing you want to be sure about. There shouldn’t be any collisions, collision risks (not colliding but very close objects), any NC program errors and CNC axis limit (over travel) problems. Verifying NC programs with the CNC simulation software will always be your basic need.

2) To Lower The First Part Machining Times That Normaly Takes Very Long Time Due To Lowered Feed Rates And Pauses

It is a common habit to minimize the feed rates to visually check the NC programs while cutting the first part. Not only feed rates are minimized to check if any collision risks occur, the cutting process is also paused many times, when the operator is not sure what will happen and he/she wants to check what is going on inside the CNC. This habit is very costly. You consume a lot of time of your CNC, therefore lower your profits a lot due to this first cut preparation and checking process. A real CNC simulation allows you to start your first cutting with real cutting feed rates.

3) Learn real cutting times

MANUSsim calculates real CNC times by taking into account CNC machine axes accelerations, decelerations and jerks. Very close results are obtained to real cutting times. CAM programs do not use machine dynamics while calculating machining times, therefore this is a huge advantage of using MANUSsim. You can use this time information, to prepare quotations and to plan your shop floor activities.

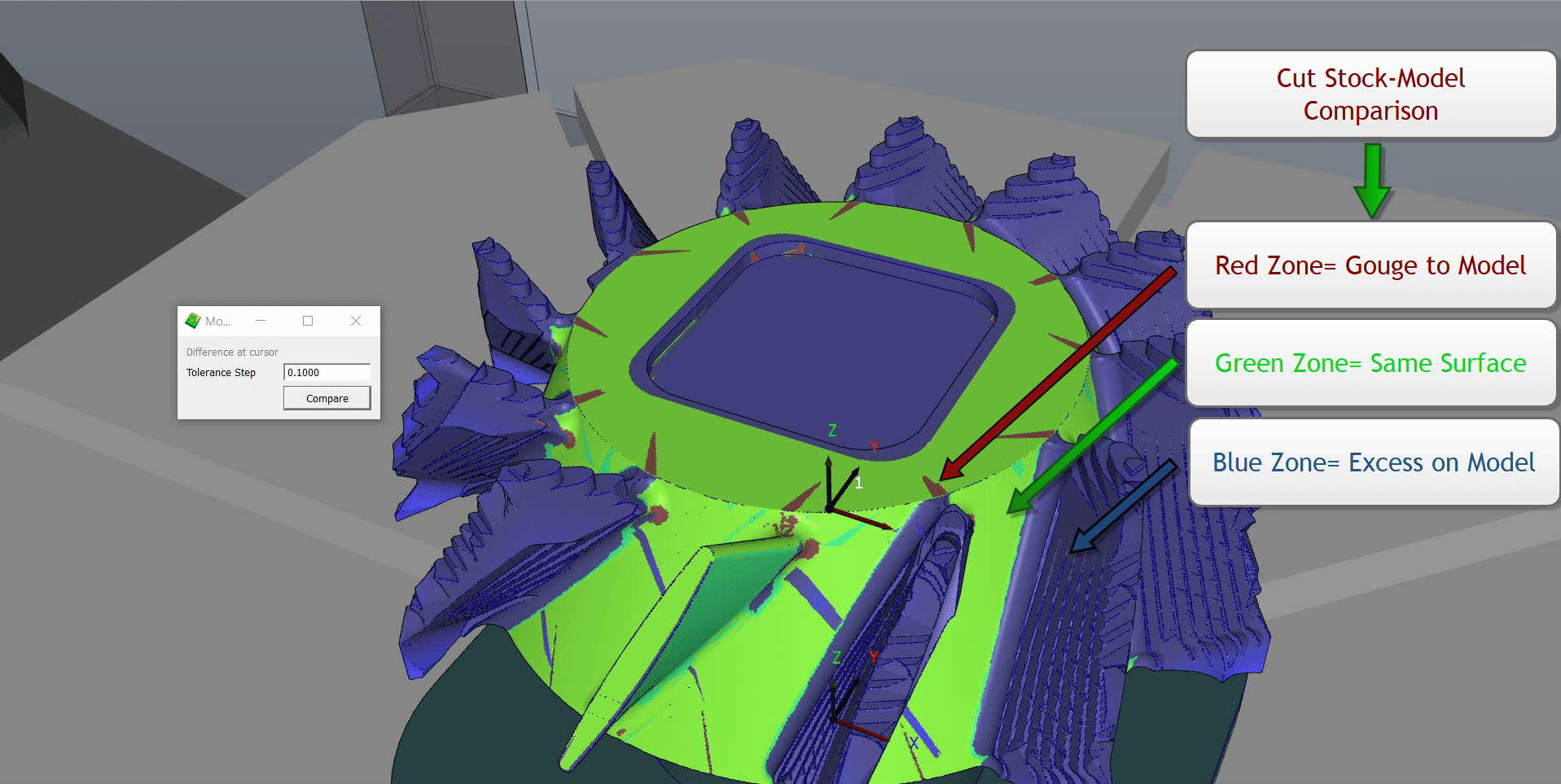

4) Stop Scraps By Analyzing Real Cut Stock

Although CAM programs can compare cut stock and target model, this comparison is not a real comparison since the cut stock is not cut with real NC code. To be exactly sure about the real cut result, you should compare the target mode with cut stock that is machined with real NC code. MANUSsim allows users to do that. The comparison can be easily performed visually, excess materials are blue and getting darker with increasing excess material amounts. Likewise gouges are in red and becoming darker red when gouge amounts increase. Green are zones where cut surfaces match target surfaces in the tolerance you define. You should also have a chance to click on the material and see the amount.

5) Control Your Cutting Conditions

You can give allowable cut depths to your cutting tools, thus MANUSsim warns you when this depth of cut is exceeded. You can also define maximum allowable cutting feed rates for your cutting tools, so you get warnings when your feed rate is above this limit.

6) Detect And Speed Up Air Cuts, Allowing Faster Cnc Machining Times And Increased Profits Per Part

Side effect of CAM programming is mostly unwanted air cuts, since you have no control on roughing algorithms of the CAM programs and many CAM programs generate unwanted air cuts and uncut touch moves. Air cuts are also generated a lot on multi-axis tool paths. This is because, it takes time to minimize cutting paths individually in each operation and most of the time CAM programmers don’t have this time to make these improvements. Another most common reason is that, when the CAM programmer’s experience is not high, the end results are not well enough. MANUSsim analyze the NC code and detects the air cuts and uncut touch only movements. The feed rates of these movements are automatically increased and you get faster CNC machining times and increased profits per part.

Nov 2021 . MANUS