Kinematics Simulation vs NC Simulation

Developments in the CNC machining industry, especially increase in the use of multiaxis and multi channel CNC machines have also enforced developments in the CAM software industry. As the use of that sort of complex CNC machines increases, CNC simulation software have started to become an industry standard in order to overcome complexities of CAM programming. Multi-axis and multi channel CNC machines have many advantages, however they are not easy to use. Using CAM programs and proper post processors can offer great deal of efficiency. But just having a proper CAM program and post processor does not always guarantee an efficient and safe machining. To overcome any errors arising from wrong NC codes and to guarantee an accurate and safe machining, CNC simulation software have to be used. Currently, there are 2 kinds of CNC simulation software in the market:

- CNC Kinematics Simulation

- Real NC Code CNC Simulation

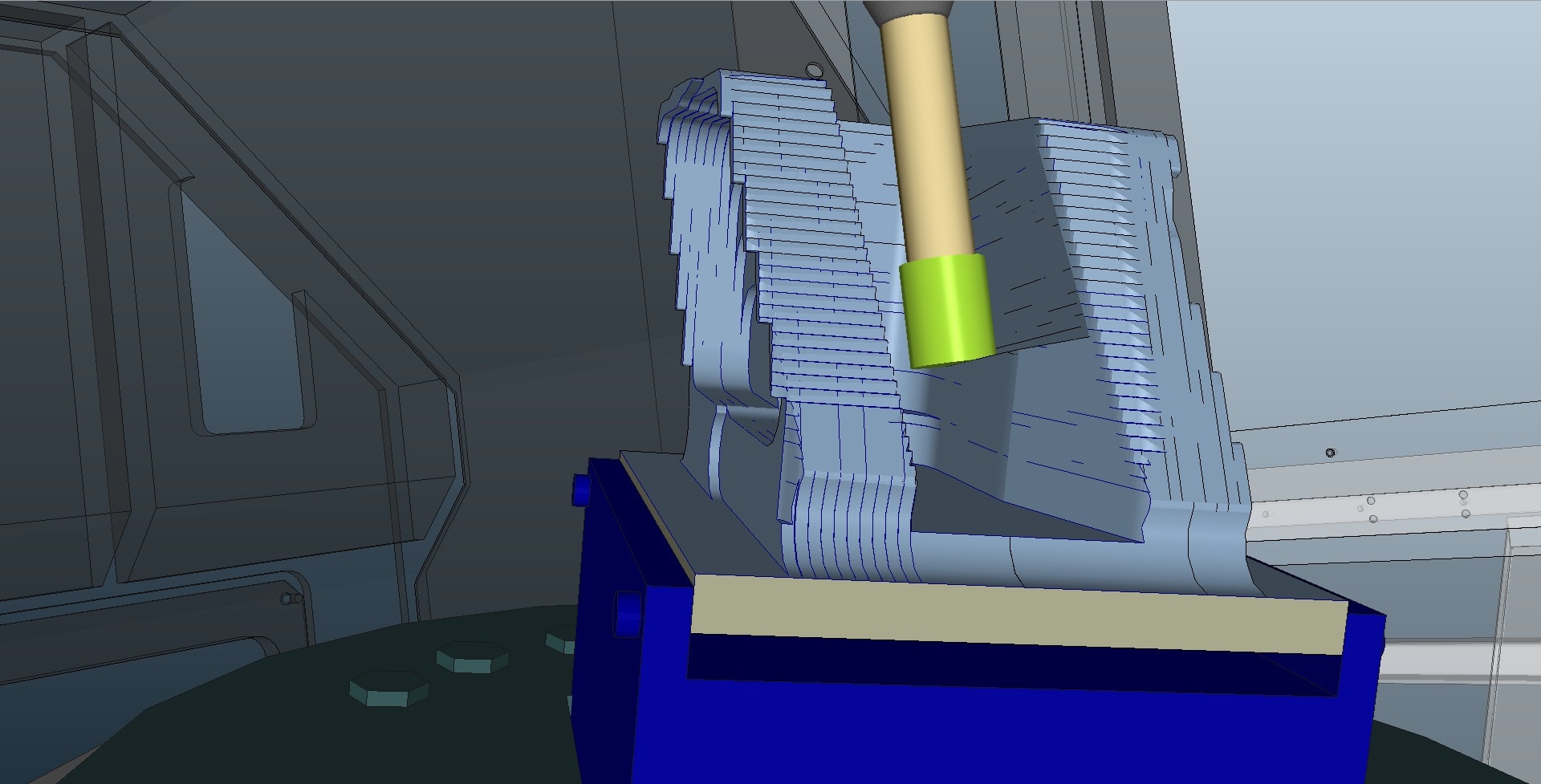

The first simulation type is 'Kinematics Simulation' which is currently offered by many CAM programs. The main characteristic of this simulation type is that it does not simulate real NC codes generated in CNC post processing stage. Instead, it uses the intermediate tool path information called in general as APT/CL code.

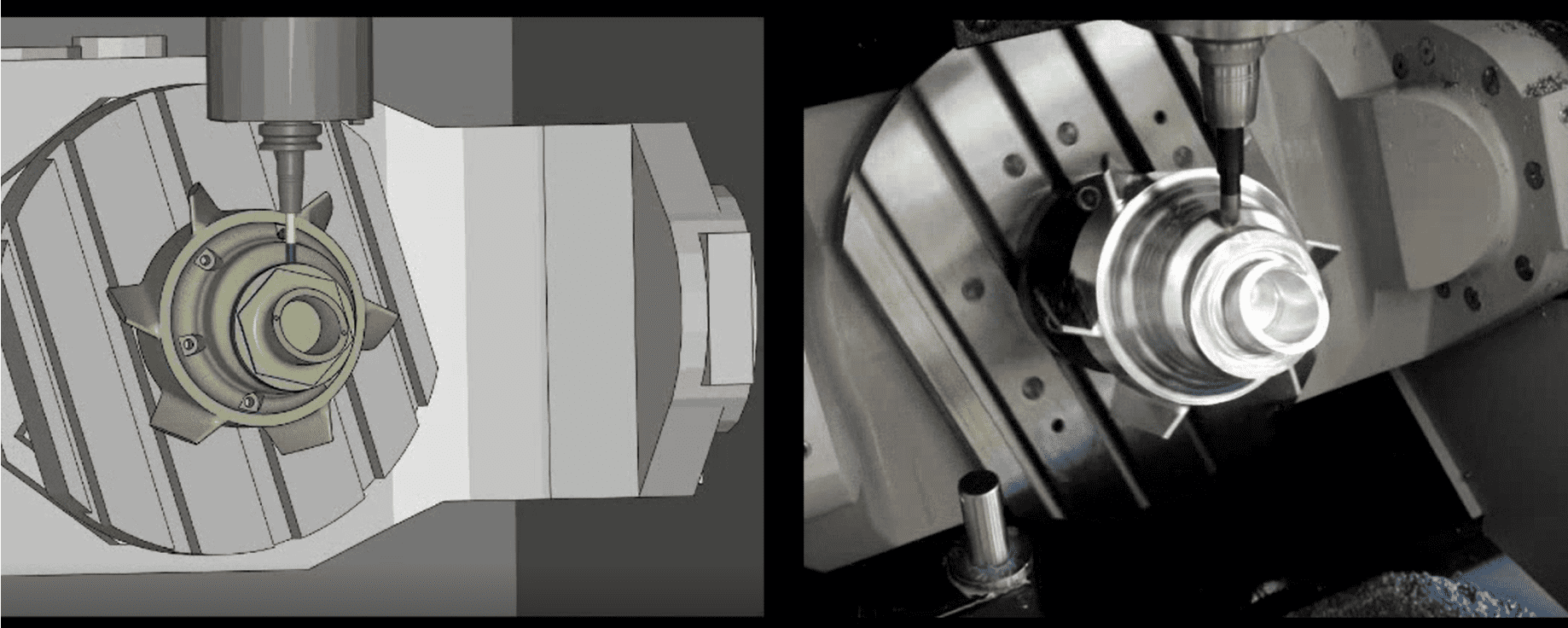

The second simulation type is “Real NC Code CNC Simulation”. This kind of simulation uses real NC code in the same way as CNC machine tool itself. It reads and interprets the real NC code like an NC controller and uses this tool path information interpreted for simulation. Therefore, this type can be called as “Real NC Code Simulation”

Kinematics simulation programs can give you an idea about how a workpiece will be machined and what the tool path will be like, but it is never a real NC code simulation. You should never rely on that kind of software. There is always a possiblity of error in the CNC post processing stage and you cannot see such errors in a kinematics simulation.

Kinematics simulation software cannot show you incorrect NC code lines that occur during CNC post processoring. If you trust your kinematics simulation results and run the NC code you generated on your CNC machine, you can encounter with terrible results like collisions, part failures and so on. Therefore, kinematics simulation programs should only be used to get a brief idea about how the machining process will be like, they should never be fully relied on.

In a NC code simulation program, all types of errors: NC code command typos, tool gouge errors, all types of collision errors, rapid cut errors etc. are detected and reported to the user. It is the only way of having a safe CNC machining process. It is very unlikely that you miss an error that you could not see both in CAM programming, CNC post processing and lastly in CNC simulation stage.

Below are the main advantages that real NC code simulation provides you. You will not have these advantages if you are using a CNC kinematics simulation, since you will never rely on the simulation results of an intermediate tool path output.

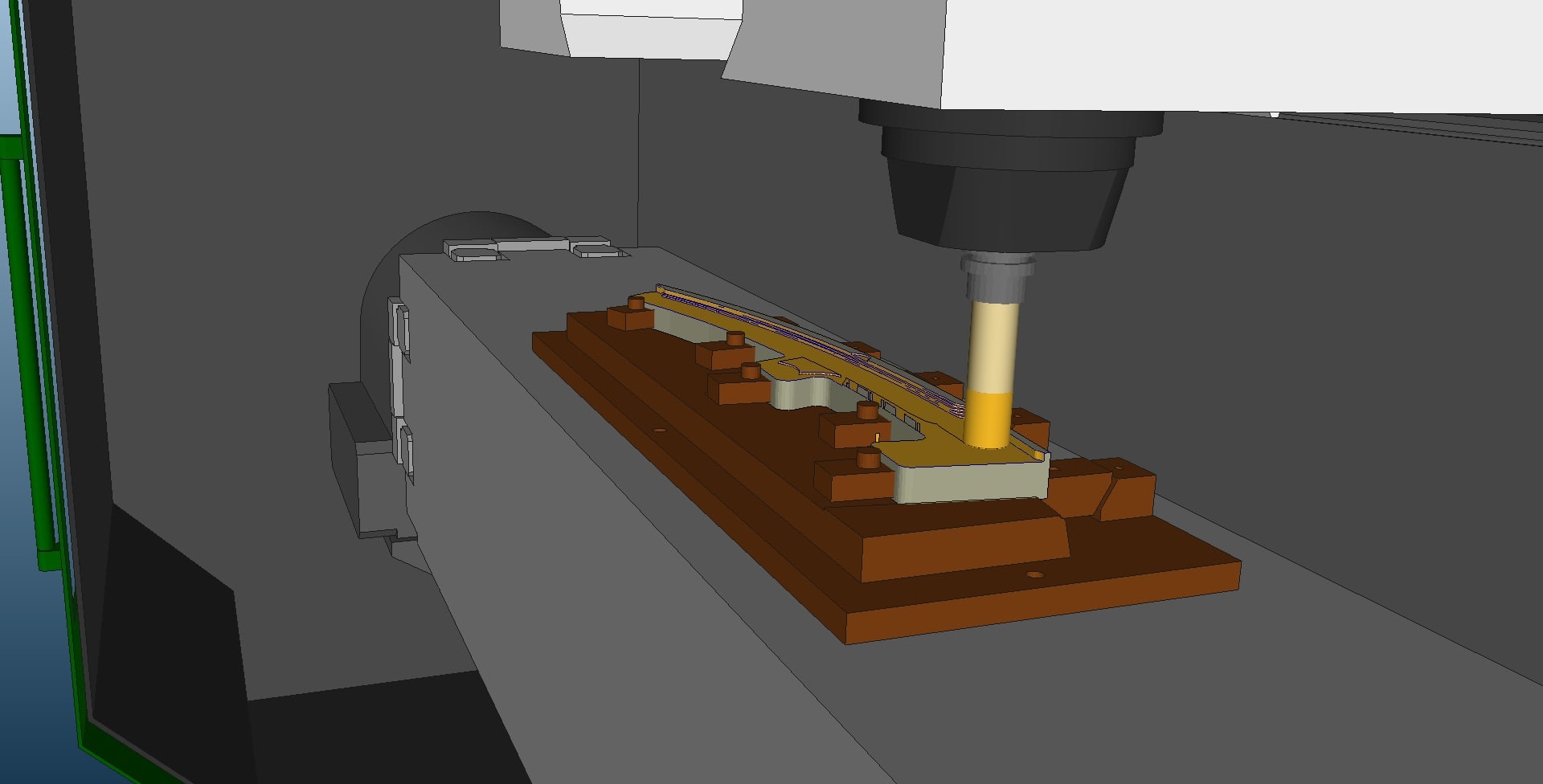

- You can observe NC code post processing errors (if exists) since post processed real NC codes are used in simulation.

- You do not need to cut a dummy part, since you observe all the machining operations in the NC code simulation.

- You can foresee and prevent critical situations like collisions or contacts between cutting tools, stocks/fixtures and CNC machine by running real NC codes on your CNC simulation.

- You can foresee and prevent critical situations like gouges on the cut stock that results from wrong NC programs.

- You can detect and correct unnecessary movements of the cutting tool by directly modifying the real NC code.

- Since you will solve all of the above-mentioned issues before running the real NC code on your CNC machine, you will cut your parts faster in the first run and the subsequent runs of the same NC code. Thus, you will machine more parts in the same time period.

We, as Manus Software, has been providing advanced CNC post procesing solution MANUSpost to our customers for 12 years. We have launched our newest product MANUSsim real NC code CNC simulation software in 2016 after 10 years of development. ManusSim is a software solution by which we mainly targeted at the problems in the CNC machining industry. MANUSsim has all the features that a real NC simulation software needs to have.

Sep 2015 . MANUS