The Importance of CNC Post Processor Editing

In the world of computer-aided manufacturing (CAM), CNC post processors play a crucial role in converting the toolpath information generated by CAM software into machine-specific CNC codes (G codes). While CAM programmers demonstrate exceptional skill in creating efficient toolpaths in CAM software, there is a significant knowledge gap when it comes to editing CNC post processors. In this blog, we will explore the issues that arise when you cannot edit your post processors and also highlight the importance of CNC post processor editing. We will also shed light on the percentage of CAM programmers who possess this valuable skill.

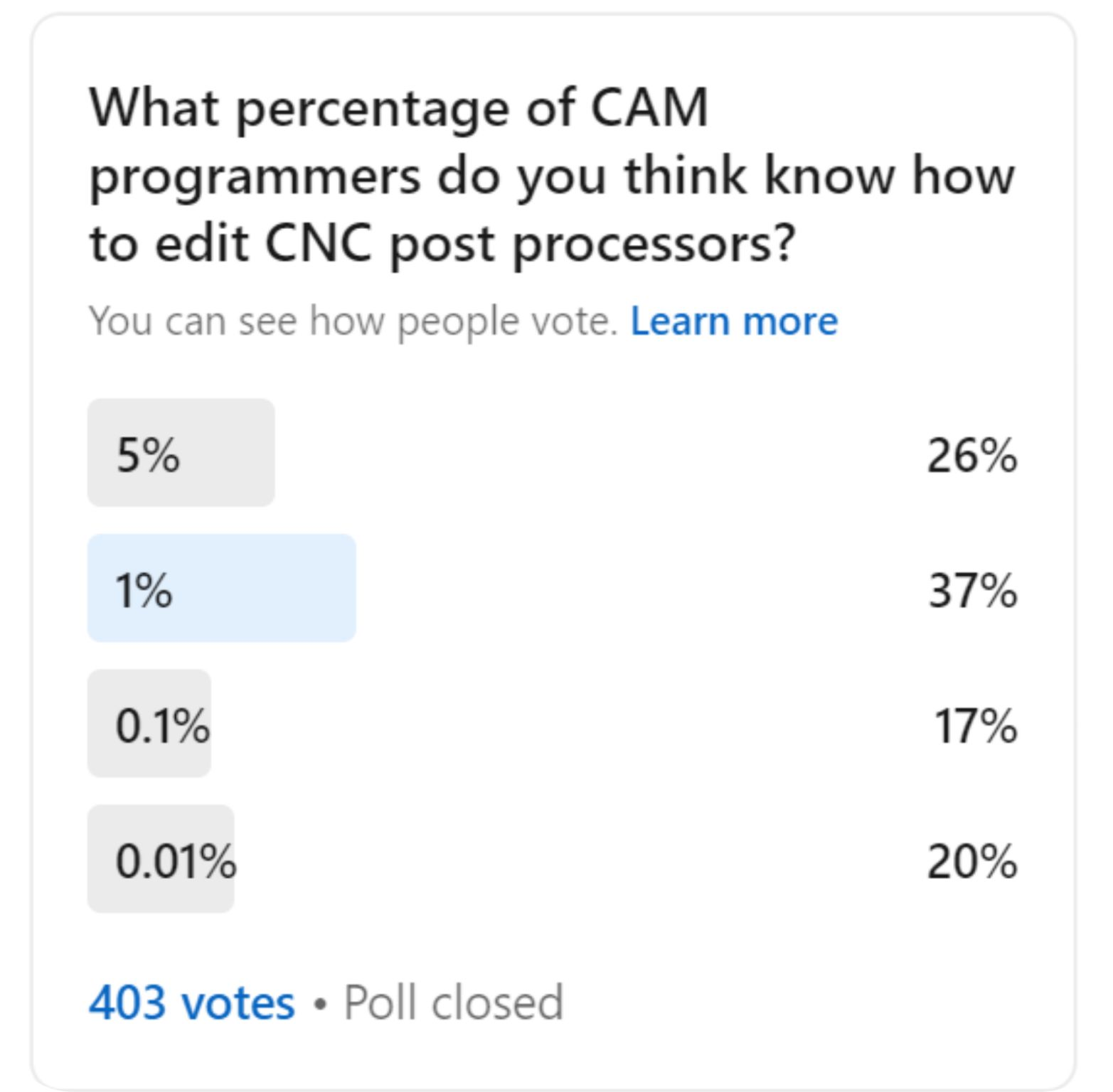

First of all, let's examine the survey we conducted on LinkedIn. We asked the participants, “What percentage of CAM programmers” do you think know how to edit CNC post processors?

The following are the results:

These results are expected, but they also highlight a significant problem in the industry.

According to the survey, 74% of voters stated that the percentage of CAM programmers capable of editing CNC post processors is 1% or less.

Don't you also think this is a significant problem? I certainly do.

When the number of CAM programmers or CNC machinists who can edit CNC post processors is extremely low, several issues arise:

1. CNC machines cannot be utilized to their full capacity as intended: Insufficient post processors hinder the full capacity utilization of CNC machines, similar to driving a Ferrari in first gear. Customization is necessary to address the unique requirements of each machine, particularly for multi-axis CNCs.

2. Wasting time with unnecessary moves: Poorly prepared post processors lead to unnecessary prolongation of CNC cycle times, resulting in inefficiencies such as unnecessary home returns. Optimal post processing is crucial for efficient machining operations.

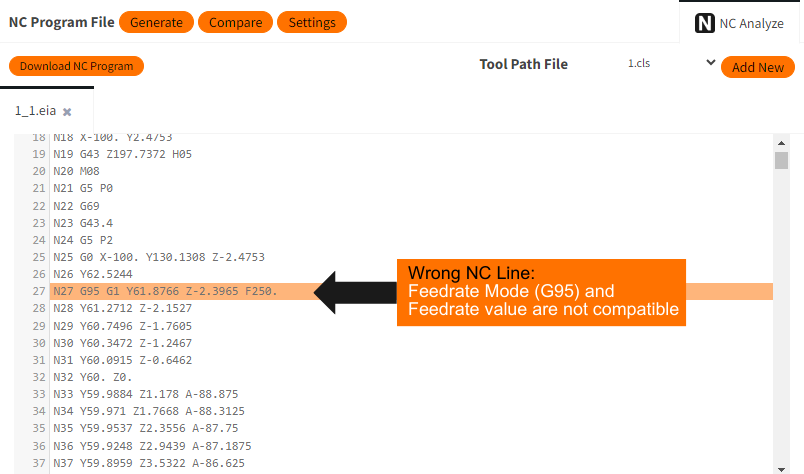

3. Incorrect post processor output can occur: Manual edits in the NC programs (G codes) may be necessary due to incorrect post processor output. In the absence of editable post processors, manual edits become a time-consuming necessity, increasing the risk of collisions on CNC machines. What happens when you manually edit an NC program:

-

Manual edits in the post processor result in time loss, taking away valuable working hours from CAM programmers and CNC machinists. Additionally, executing manually edited NC programs on the CNC may require decreasing feed rates due to uncertainty, resulting in substantial time losses during the CNC machining process.

-

Each manual edit made to the NC program (G codes) increases the risk of collisions on the CNC machine. Manual edits pose significant risks that can lead to CNC machine collisions. Therefore, it is strongly advised to refrain from making manual edits to your post processors.

4.Waiting consultancy from CAM vendors can delay the work: CAM vendors are often relied upon for post editing, but they often lack sufficient expertise. Technical support from CAM vendors may not effectively resolve post processing issues since they may need to consult someone at the CAM company headquarters, causing delays in receiving a response.

5. Expensive post processor customization support may not be enough: When all other options have been exhausted, the only remaining choice is to incur significant expenses for custom CNC post processor editing. However, it is important to note that even with expensive post processor customization support, there is no guarantee that all post processing problems will be resolved.

To overcome all these difficulties, learning how to edit CNC post processors is crucial in the CNC machining industry. Interestingly, CAM companies seem to ignore this major issue, claiming to have a huge library of post processors that perfectly fit their customers' needs. However, this is mostly not true. Customization is necessary for almost every post processor, particularly for multi-axis CNCs.

Moreover, most CAM companies have outdated CNC post processor editors (text-based editors) that are very difficult to use, requiring programming expertise.

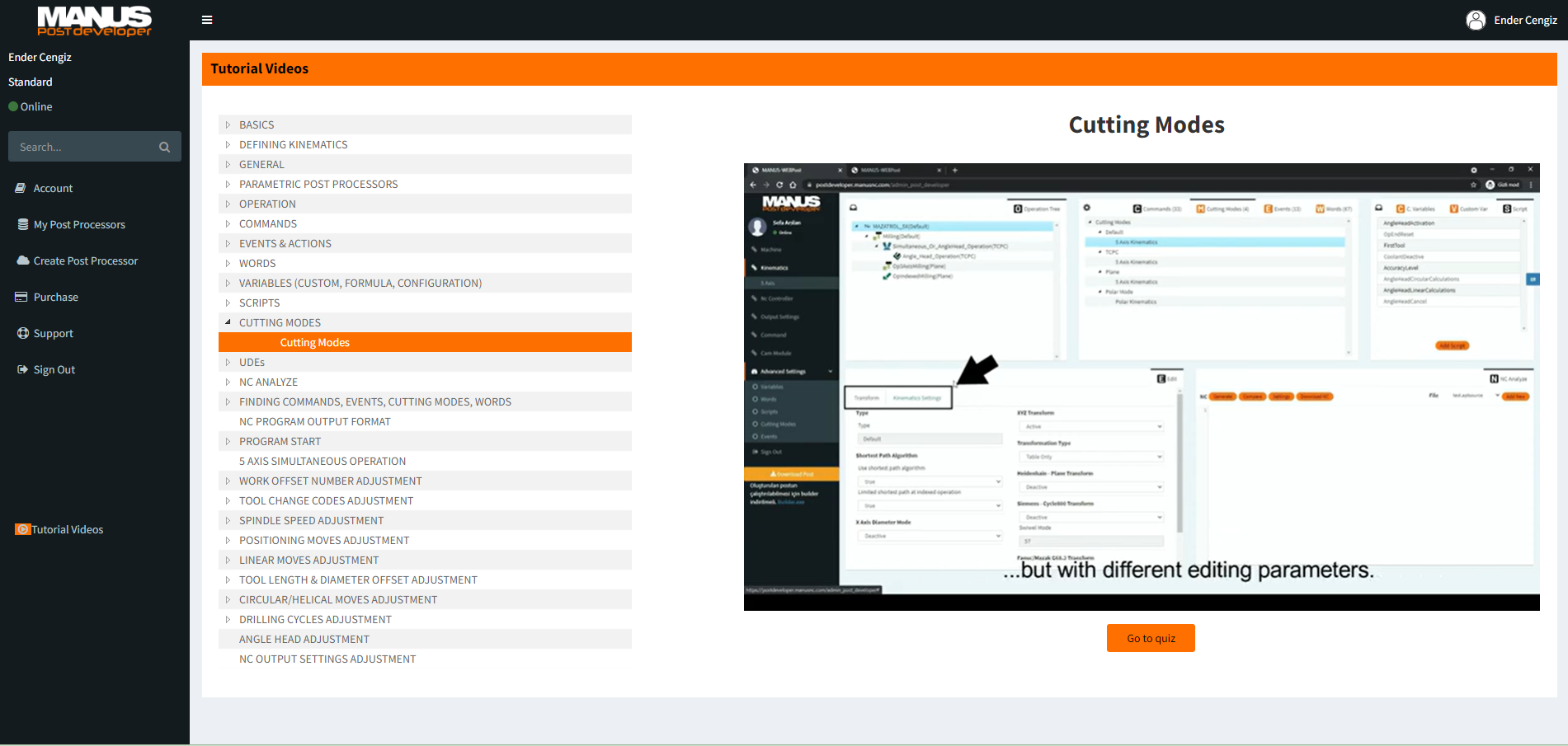

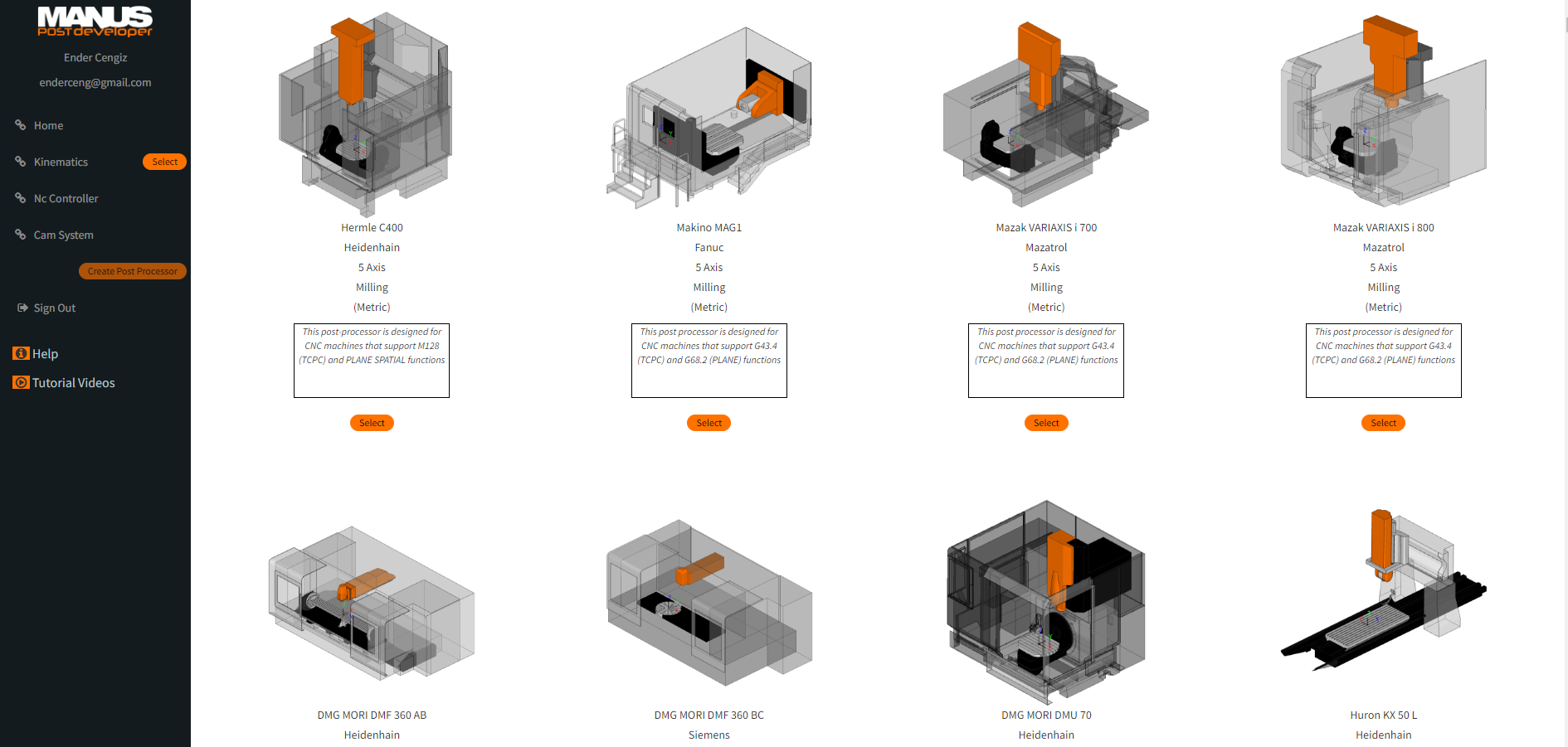

At MANUS, we have a solution to overcome this problem. We not only have the world's most easy-to-use and powerful CNC post processor design tool: “MANUSpost developer”, but also provide extensive tutorial videos to train users on using our post developer.

Additionally, we offer a large library of ready-to-start post processors, eliminating the need to start from scratch when creating your post processor. Furthermore, our platform features extremely powerful post debugging capabilities to help you analyze your post processors quickly.

We have also embedded the world's first automatic error detection system in our post developer. If you make a mistake while editing your post processor, MANUSpost can automatically detect it using predefined rules.

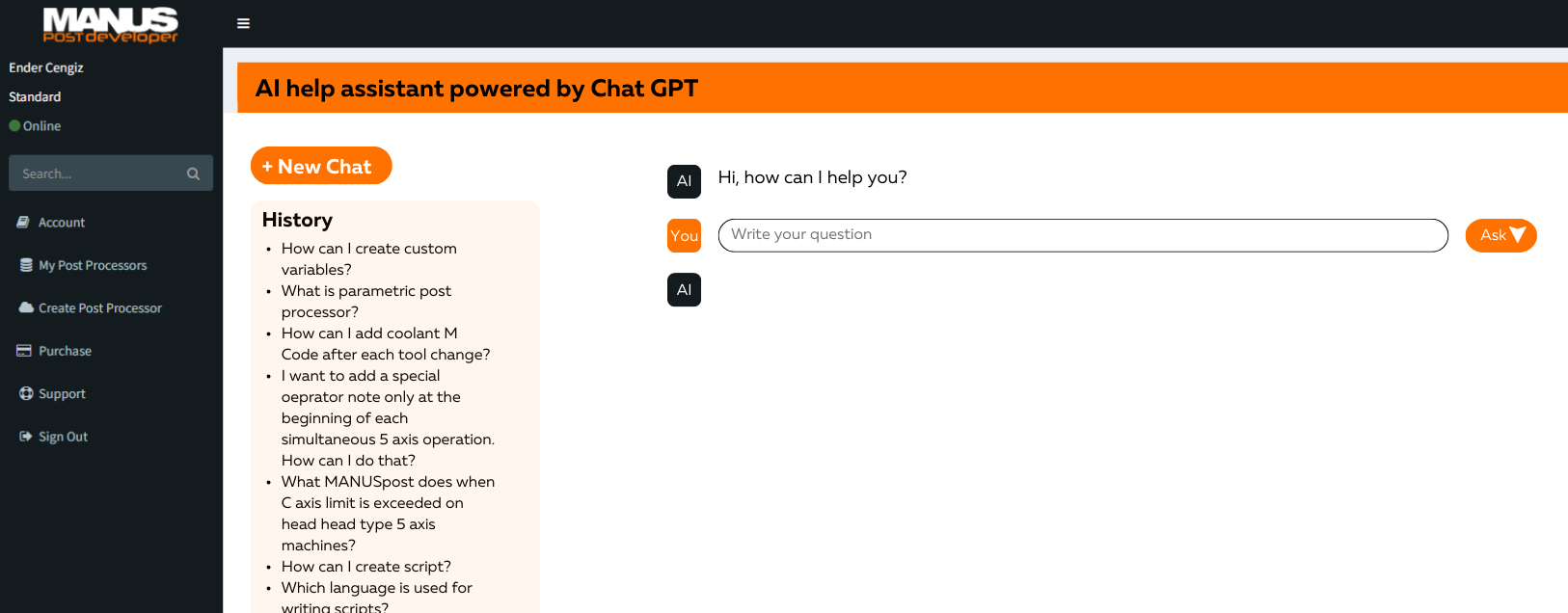

We also have a Chatgpt Powered AI Help, where you can ask any questions you want to learn how to use MANUSpost developer.

In conclusion, we highly recommend every CAM programmer to start using "MANUSpost developer." It is a cloud-based application that is completely free to use. You can sign up for the platform at no cost.

We believe it is crucial for every CAM programmer to take charge of editing their own CNC post processors. By recognizing the importance of post processor editing and actively investing in acquiring this skill, CAM programmers can unlock new possibilities in CNC programming. Embracing post processor editing empowers programmers to optimize machining processes, resolve compatibility issues, and achieve superior results with their CNC machines. Let's embrace the art of post processor editing and unleash the full potential of CNC programming!

Login to MANUSpost developer now for free: https://postdeveloper.manusnc.com/login

Jul 2023 . MANUS