Benefits Of Using CNC Simulation Software

Usage of multi-axis CNC machines (4-axis or more) has been increasing continuously for more than a decade. In the aviation and defense industries, multi-axis CNC machines have already become an industry standard. Using complex multi-axis CNC machines enforces the use of advanced CNC software programs like CNC simulation or CNC post processor.

The first one of these special software type is the CAM software. CAM software programs allow users to prepare tool path on 3D models. CAM software has been widely known and used in the industry for almost 30 years. The last 10 years, CAM software capabilities excessively increase to overcome difficulties on multi-axis CNC programming. The progress on the CAM software continues with the addition of new tool path types like trochoidal cuts and new cutting tool types like barrel tools.

The second type of these special software is the CNC post processor software. Importance of CNC post processors is growing exponentially and huge percentage of multi-axis CNC owners have been continously investing on special advanced CNC post processors for their CNC machines due to safety, accuracy and efficiency reasons in their CNC machining process.

The third special software type is the CNC simulation software. Just like CNC post processors, the importance of CNC simulation and the need of that kind of software for multi-axis CNC owners have been on the rise continously. So what is CNC simulation software exactly?

To make it short: CNC simulation software can give the CNC machine owners the opportunity to test the NC codes before running these codes on the CNC machine tool itself.

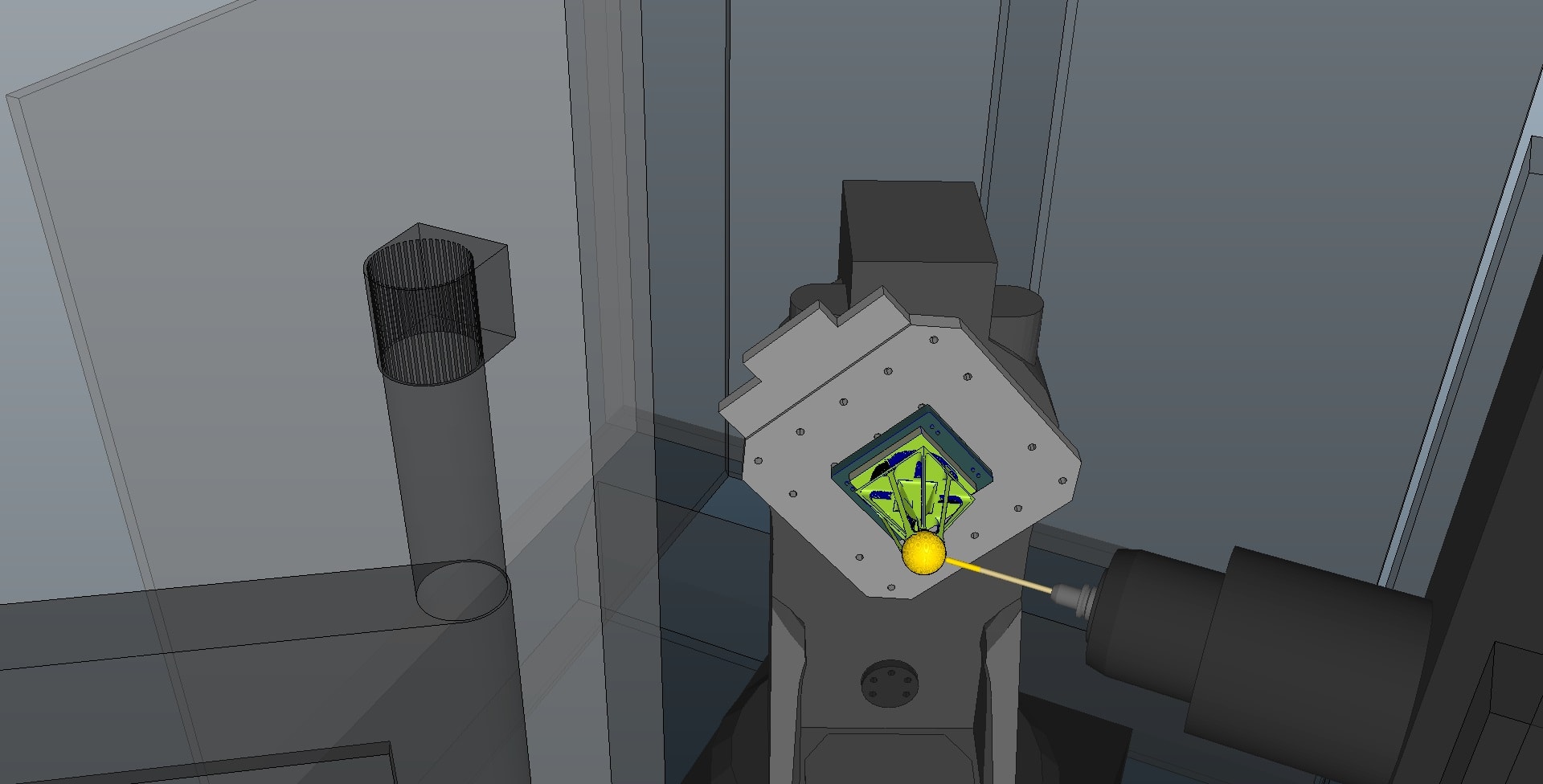

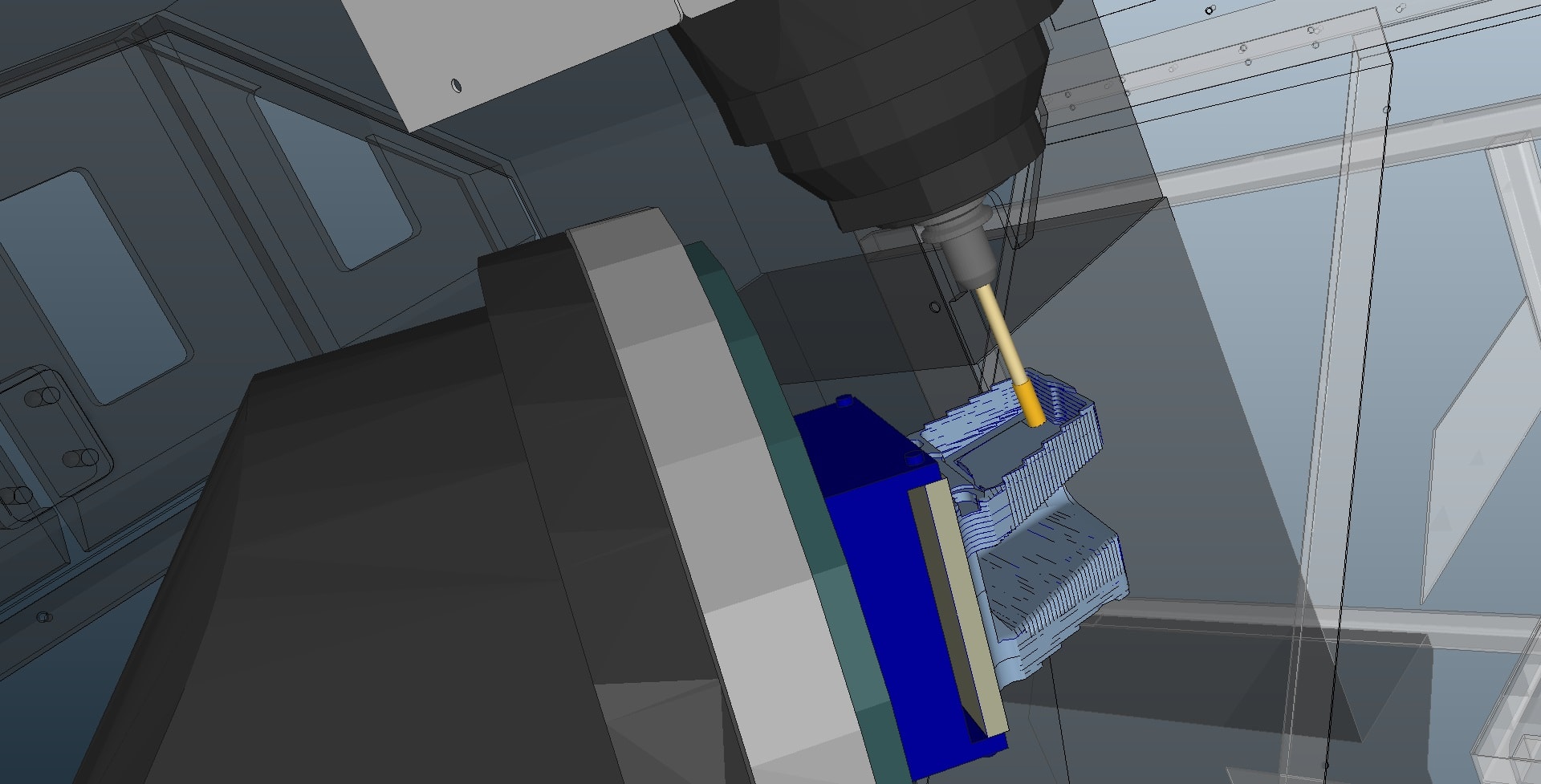

These simulations emulate the real NC codes prepared and simulate the real CNC machine movements. Moreover, it shows all cutting tools, holders, fixtures, vices, clamping parts and stock material 3D models in the simulation environment.

By simulating the real CNC movements and displaying all the machine setup 3D models, all types of collisions, model gouges, rapid cuts, NC code errors can be detected easily.

Although some of the CAM programs in the market have CNC simulation modules, in fact they most of them cannot simulate real NC codes. What they simulate is just the kinematic movements of the CNC machine that results not from real NC code, but results from emulating the intermediate tool path format like APT/CL files or similars. We call them “CNC Kinematics Simulation”. You should never rely on the results of these kind of simulation since these kinds will never give you the real result since they do not emulate and simulate real NC code.

The second kind of the CNC simulation software is the one that we call “Real NC Code CNC Simulation”. That kind of software simulates real NC codes and also provides other special features for users like real collision control through real NC code running, cutting tool length optimization, real model gouge detection, real cutting time calculation, tool path optimization of the real NC code and many more.

There are not many real NC code CNC simulation software in the market. Only big size companies prefer to invest on such software solutions. However, the importance of these software has started to be understood more by smaller and mid-size companies.

The second main reason of their insufficent use is their high costs. Despite the fact that, its importance and necessity are understood more, their prices are really high that restricts small size companies to make invest. As a result, small-size companies that cannot afford these prices mostly postpone these investments or forced to buy or prefer insufficient CNC kinematics simulation modules that are available in many CAM software programs.

In accordance with demands of our customers, we continuously develop new features and improve our CNC simulation software that simulates the real NC code, MANUSsim since 2008. As a result of 8 years of our effort, we have presented our CNC simulation program in 2016. MANUSsim, with affordable price and professional and advanced software features are available for the CNC machining industry.

If you would like to learn more about why MANUSsim is a valuable tool for CNC machining, you can visit the following link

Jul 2015 . MANUS