Myths and Facts About CNC Simulation

There are many myths about CNC simulation but we will examine the widely believed ones today. If you cannot decide if you should buy a CNC simulation or not, this blog will be an excellent guide for you.

MYTH 1: CNC simulations inside CAM systems simulate true G Code

Even all the CAM companies tell you that they have the true CNC simulation, this is not true for many CAM systems in the market. Only a few of them are capable of simulating true G codes. The remaining majority of CAM software simulates the intermediate tool path data (Apt/Cl etc.).

If a CNC simulation software cannot simulate the true G code, it cannot be considered as a true CNC simulation software. So we recommend you to ask if the CNC simulation software can simulate the true G code before you buy one.

MYTH 2: CNC simulations inside CAM systems guarantee safe CNC machining

CAM systems that do not have true G code simulation capability should not be used to verify cutting tool paths. It is too risky to use this kind of false CNC simulation to validate the machining process. Because the tool path data will show you what happens in the CAM environment instead of what will happen in your CNC for real. Therefore it will not save you from gouges, scrap parts, damaged CNCs and many other accidents.

The only way to have a safe CNC machining process is to use true G code CNC simulation software instead of fake CNC simulations that simulate intermediate tool path data (Apt/Cl etc.).

MYTH 3: It is always more advantageous to use true G code CNC simulation inside CAM systems

If it is a true G code simulation, then using CNC simulation inside CAM systems can bring a benefit of directly simulating the operations on a CNC simulation without using a third party simulation software.

However, there are also some disadvantages you should consider:

-

If your company uses two CAM systems at the same time (one has true G code simulation capability and the other does not), you cannot use the G code simulation in one CAM system with the other CAM you have.

-

Let’s say you are using a CAM system that has a true G code simulation capability. However you want to switch to another CAM system since the new one has many benefits and is superior to the one you have. This will be a very hard decision for you because you will lose all your investment on your previous CAM system, including the CNC simulation module and all CNC machine simulation integrations you pay additionally on your previous CAM system.You need to make the same CNC simulation investment again for your new CAM system.

Although it is advantageous to use the CAM and CNC simulation in the same software, there is always a risk the same error will be interpreted as true if they are developed in the same environment. Using a third party standalone CNC simulation software is like looking at the G code and the whole process with a different perspective.

MYTH 4: Using third party CNC simulation software is difficult.

It is not difficult to use third party CNC simulation software that operate independently from CAM systems. Because third party CNC simulation programs that are available on the market have integration with many different CAM systems. With such integrations, it is very easy to transfer 3D models, cutting tools, tool holders and work offset locations from CAM systems to CNC simulation with a few clicks.

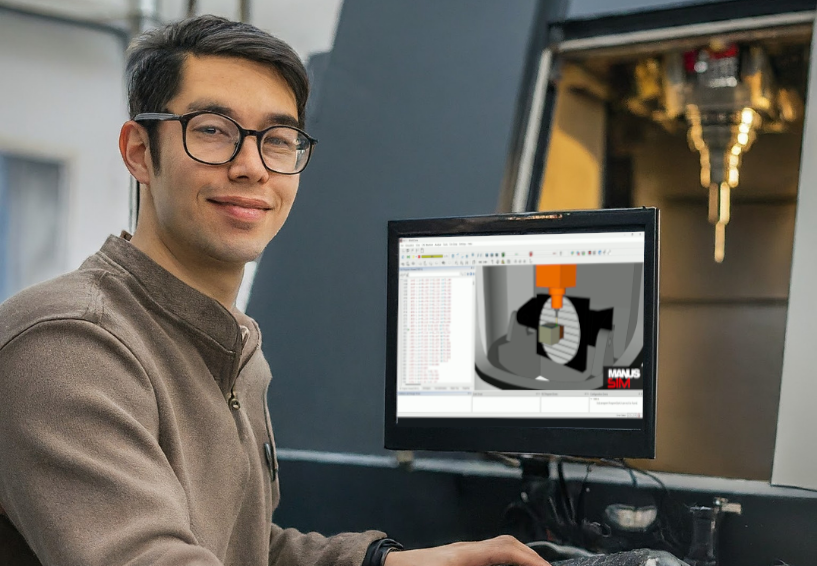

We would like to inform you that MANUSsim CNC simulation already has integration with more than 10 CAM systems that are the most popular and we continue to develop integration modules for many other CAM systems too.

You can check out how easy it is to transfer the data from a CAM program to MANUSsim, here are some videos:

1. https://www.youtube.com/watch?v=LDhyWBd7aBM

2. https://www.youtube.com/watch?v=nfnlrqmaYbs

3.https://www.youtube.com/watch?v=3mSfw44-Yks

MYTH 5: Using third party CNC simulation software is risky.

Well, it is not risky to use a third party CNC simulation software at all. As mentioned above, using third party true G code CNC simulation is much safer than the simulation that uses tool path data(APT/Cl, etc.) inside CAM systems.

Moreover, employing a third party CNC simulation significantly enhances speed compared to conducting G-code simulations within CAM systems. This efficiency stems from the inherent limitations when utilizing CNC simulation within CAM software, where a user must allocate their CAM software license exclusively for CNC machining simulation. Consequently, CAM programming and CNC simulation can not be done together at the same time under a single user license, but leveraging a third party CNC simulation does not allocate the CAM license for simulating the CNC machining process.

Hence, users retain the ability to utilize their CAM software license for programming while concurrently benefiting from a third party CNC simulation.

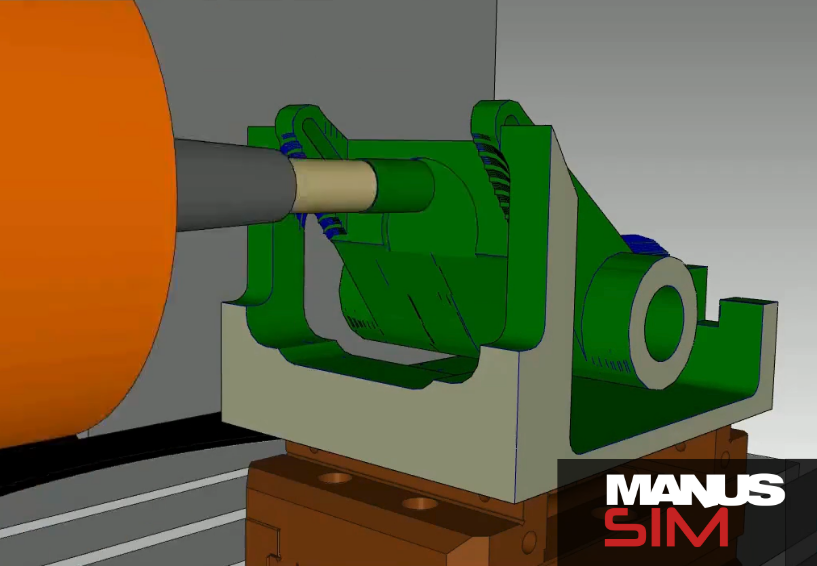

MYTH 6: CNC simulation is only needed for complex part machining and it is a waste of time for most of the parts.

That is probably one of the most widely believed myths. Of course collisions on CNC machines can always happen even when you are cutting the most simple parts on earth. When you think about your past experiences, you will confirm that it's true without any doubt.

You know the smallest mistake can cause the biggest and most expensive problems in machining. That is why we recommend you to use real CNC G code simulation software before every process to prevent accidents.

MYTH 7: CNC simulation is a luxury. You need to pay a lot for software itself and you will also pay for simulation integration of each CNC machine tool that you have.

This myth is not so wrong however it is not true as well. CNC simulation software is not the cheapest solution for sure. But we can assure you that using CNC simulation is not a luxury since luxury means something adding to pleasure or comfort but not absolutely necessary. But CNC simulation is definitely a necessity.

When you think about the collisions that are prevented, parts that are not scrapped and the time you gain on your production, CNC simulation software fees are worth their price.

You can contact us now to get your price/performance high quotation. We are offering really affordable prices both for CNC simulation software and integration of CNC machines to the simulation.

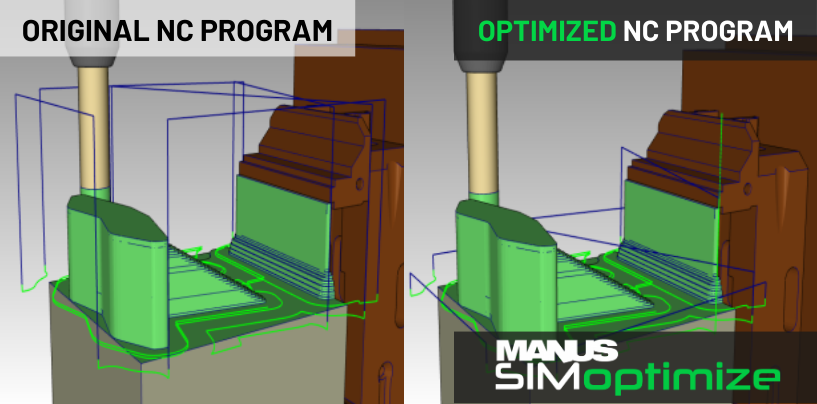

MYTH 8: CNC simulation can only be used to verify NC codes.

This is not true for most of the CNC simulation software. A CNC simulation software should be capable of performing additional tasks like:

-

Optimizing cutting tool lengths,

-

Controlling cutting conditions (max feedrate, max spindle, max depth of cut control etc.)

-

Optimizing uncut movements (by deleting them or increasing their feed rates),

-

Optimizing cutting feed rates (by calculating the volumetric material removal amounts at each cut, variable feed rates can be utilized instead of fix feed rates),

-

Optimizing NC programs and adding special control macros to perform specific tasks, and so on...

If your CNC simulation software does not offer you those features, maybe you should consider getting a new one.

MYTH 9: You need to train yourself a lot to use CNC simulation software.

This depends on the CNC simulation software you are using. A CNC simulation software should not be difficult to learn and use. So if you can find the right CNC simulation for you, this myth will not become true at all.

As MANUS, we are always working on how to simplify things for end-users. We already have automatic transfer capabilities from some major CAM systems and we continue to work integrating more CAM systems to MANUSsim CNC simulation software.

We can tell that it only takes half of a day to train a new user to learn to use MANUSsim. We have a detailed help section and also with your questions you couldn’t find any solution, our experienced engineering team is ready to help you.

You can try yourself and see how easy it is to use MANUSsim: www.manusnc.com/en/manussim

Conclusion:

You shouldn’t believe any myths about CNC simulation software before checking out the truth. Because if you have a CNC machine or working with one, the most important thing you should know is to keep your CNC, parts and cutting tools safe. Therefore you should find the right CNC simulation that meets your needs properly.

MANUSsim can be the CNC simulation software that meets all your needs. If you would like to get detailed information about MANUSsim or get a free demo, you can contact us now.

Feb 2024 . MANUS