MANUSsim

POWERFUL, FAST & AFFORDABLE

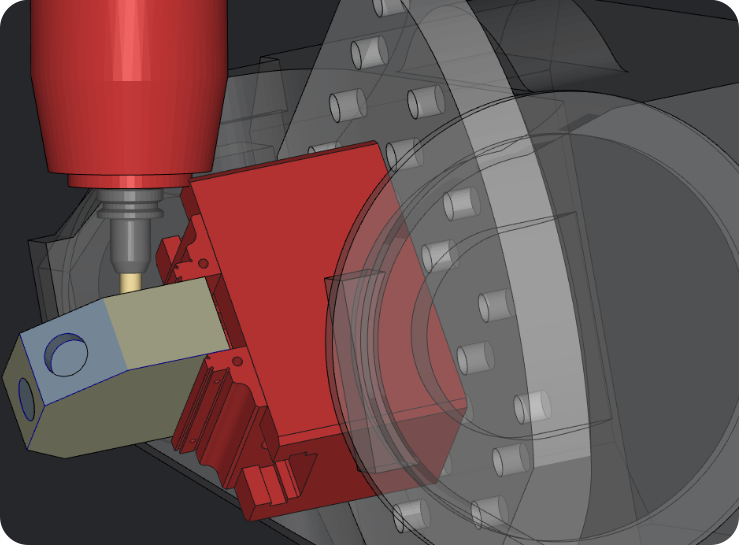

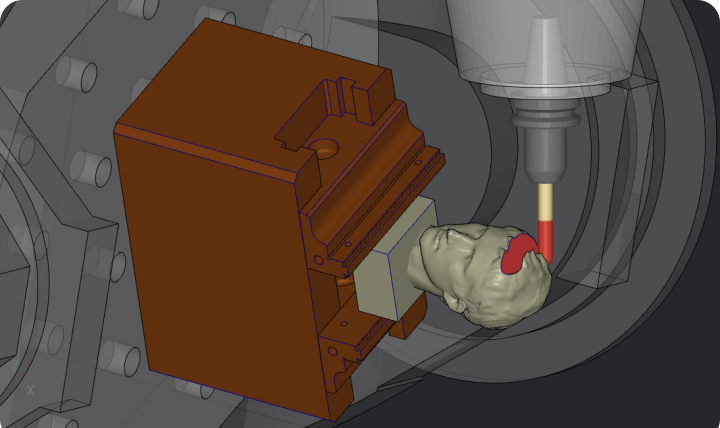

CNC SIMULATION

THAT SIMULATES REAL NC PROGRAMS

Developed for over 15 years, MANUSsim offers a wide range

of advanced features. Thanks to its afforable prices,

you can now start simulating and verfying your NC programs

on your actual CNC machine twin.